It will go higher and further in the field of wire and cable

188-3370-2558

It will go higher and further in the field of wire and cable

KeyWords: antong

Professional focus, service to the heart, perfection

Strong and guaranteed

The company has equipped 2 high-pressure cross-linking three-layer co extrusion production lines with advanced level,

Production equipment such as wire drawing machine, stranding machine, cable forming machine, shielding machine and extrusion unit

It has passed iso9001:2015 quality management system and iso4001:2015 environmental management system

ISO 45001:2018 and other occupational health and safety management system certification

Only qualified and unqualified cables can be inspected to ensure the products are delivered

Pass rate 100%, authoritative test report, multiple patent certifications

Fully implement the requirements of quality management system and strictly control the quality in the production process;

Nationwide after-sales service network system, let you find us at any time!

The manufacturer provides direct sales, avoids the superposition of intermediate interests, optimizes raw material suppliers, outsourcing manufacturers and purchasing processes, reduces raw material costs, optimizes product structure and production processes, ensures quality and saves production costs

The company has a professional after-sales service team to help you solve the pre-sale, after-sale and other problems at any time, so that your production is more smooth and production efficiency is greatly improved;

Pre sales: free consultation, professional purchasing personnel to help understand the needs of products;

During sale: follow up the whole process of sale, and can provide customized service to meet the demand;

After sales: large scale warehouse reserves professional logistics transportation to ensure the supply speed.

The leading team is a young but experienced team, with young people's unique vigor, drive and innovation awareness; with a number of high-quality professional research and design personnel and perfect after-sales service system.

Case

Case

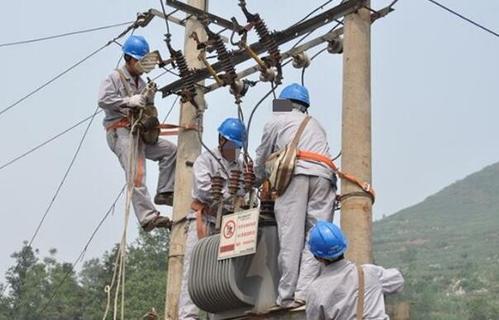

State Grid Yingkou Power Supply Company 10kV new second line, Xinglong line and other line reconstruction projects and network diversion projects.

Case

Case

Power supply transfer project of "three supplies and one industry" of Huludao Zinc Plant

Case

Case

Low voltage power cable, yjlv, aluminum, 50, 4-core, ZC, 22, general procurement contract.

Case

Case

State Grid Huludao power supply company, Suizhong Sujia and other 40 three-phase imbalance treatment.

Case

Case

State Grid Liaoning Huludao power supply company, Jianchang 10kV, Dazhangzi and other 11 lines, 36 sets such as Beidi, three-phase imbalance treatment

Case

Case

State Grid Jilin Electric Power Co., Ltd. purchases steel core aluminum strand, JL / G1a, 150 / 20 and other products of Hebei Antong wire and cable Co., Ltd.

What are the requirements for the production of steel cored aluminum wire? 1、 First of all, we start from the material selection: the galvanized steel wire used is not allowed to have joints. 2、 Secondly, the requirements of welding points are discussed from the point of production No joint is allowed for any round aluminum wire in 1.7-strand aluminum strand. Except for the joint before the finished drawing die. 2.7 or more strands of aluminum and round aluminum wires in steel core aluminum wires are allowed to have joints. However, the distance between the two joints on the finished strand shall not be less than 15m. It should be smooth and round at the joint. The aluminum wire joint shall be resistance butt welding, cold pressure butt welding or resistance cold heading welding. The resistance butt welded joint shall be annealed, and the annealed length shall be at least 200 mm on each side. The mechanical strength of the joint does not need to reach the mechanical strength of the aluminum wire matrix. 3、 Requirements for stranding 1. The surface of round aluminum wire shall be smooth. 2. It shall be twisted evenly and tightly.<了解详情>

Good products and high-quality service concept are the key to the development of power cable enterprises. From various factors affecting the competitiveness of power cable enterprises at present, quality and technology, raw materials and internal management are the most important factors determining the competitiveness of enterprises.<了解详情>

Continuous scratch of conductor is the most common cause of corona, and corona is one of the most important causes of power loss in power system. In order to avoid the occurrence of wire scratch, the following aspects should be controlled in the production: first, consider from the conductor itself. First, ensure that the aluminum rod is not damped, which causes the aluminum chips in the working area of the drawing die hole to stay, and the lubricating oil can not all enter the working area, so that the aluminum wire pulled out is not round and smooth. The second is to ensure that the drawing oil is clean and free of moisture. In the process of wire drawing, the drawing oil is in a high temperature state when it enters the working area from the lubricating area. If there is certain moisture in the drawing oil, the lubricating oil will be diluted, and the lubricating effect will be greatly reduced, resultin<了解详情>

Without qualified raw materials, it will be like "a skillful woman can't cook without rice", so this is also the most basic factor determining the quality of ACSR. Therefore, to ensure the quality of the steel cored aluminum wire, it is necessary to ensure that the raw material environment in the production line also has quality and quality assurance, which can continuously supply the high-quality steel wire and aluminum wire materials of the steel cored aluminum wire.<了解详情>

What do you think of "replacing copper with aluminum" For the wire and cable industry, the most obvious material replacement is to use aluminum conductor instead of copper conductor. In the relative cost of copper and aluminum conductors, we need to consider the price, specific gravity, conductivity and other factors, in order to get the real answer whether using aluminum conductors can save costs. Copper is heavier than aluminum. The specific gravity of copper is 8.9g.cm3, and the specific gravity of aluminum is 2.7g/cm3. That is to say, under the same conductor specification, the weight of copper conductor is 3.3 times that of aluminum conductor. However, the conductivity of aluminum is only 61% of that of copper, that is to say, the cross section of aluminum conductor is 61% larger than that of copper conductor under the same transmission current. Therefore, in terms of conductor weight, to make the two conductors have the same carrying capacity, the weight of copper conductor is about twice that of aluminum conductor. In addition, the price ratio of copper to aluminum is about 3.5, so the cost of equivalent copper conductor is seven times that of aluminum conductor. Of course, the simple cost comparison mentioned above does not explain the whole problem. Because the cable product is limited by the standard conductor specification, it is impossible to buy the aluminum core cable with the same conductivity as the copper core cable. Therefore, if the cable is made of aluminum conductor, the aluminum conductor with larger cross section must be used. Experience shows that under the condition of equal carrying capacity, the conductor section of aluminum core cable should be twice that of copper core cable. Since the cross-section of the aluminum conductor is twice that of the copper conductor, the subsequent increase in the insulation, sheath and armor materials of the aluminum conductor weakens the price advantage of using the aluminum conductor. That is to say, the price advantage of aluminum and copper is not great, because the conductor is only a small part of the cost of the whole cable after all. Taking 70mm2 copper core cable as an example, the cost of copper conductor accounts for about 65% of the cost of the whole cable, while the cost of 120mm2 aluminum core cable with equal current carrying capacity can be saved by 23.5%. If the cost of copper conductor accounts for 80% of the cost of the whole cable, the cost savings of aluminum core cable with equal current carrying capacity can reach 46%. Only when the cost of copper conductor in the cable drops below 50% of the cost of the whole cable, the aluminum core cable will lose its cost advantage. At present, the cost of most copper core low-voltage cables and many medium voltage cable conductors has exceeded 50%. Therefore, compared with copper core power cables, aluminum core power cables have obvious advantages in cost saving.<了解详情>

1. When storing the cable, it is strictly prohibited to contact with acid, alkali and mineral oil, and it shall be stored in isolation from these corrosive substances; 2. There shall be no harmful gas damaging the insulation and corroding the metal in the warehouse for storing cables; 3. Try to avoid storing cables in the open air in an exposed way, and the cable reel shall not be placed horizontally; 4. During the storage period, the cable shall be rolled regularly (once every three months in summer, and may be extended in other seasons as appropriate). When rolling, roll the storage plate downward and upward to prevent the bottom from moisture and rot. Always pay attention to whether the head of the wire is intact during storage; 5. The storage period of the cable is limited to the ex factory period of the product, generally not more than one and a half years, and the longest not more than two years; 6. During transportation, it is strictly prohibited to drop the cable or cable reel with cable from a high place, especially at a lower temperature (generally around 5 ℃ or below), throwing or dropping the cable may lead to cracking of insulation and sheath;<了解详情>

1. In the process of line design, the capacity of the site shall be accurately verified, and the possibility of new capacity in the future shall be fully considered, and the appropriate type of conductor shall be selected. The larger capacity, the thicker conductor should be selected. Line design and reasonable selection are the key steps to prevent overload. If the design and selection are improper, it will leave a congenital hidden danger that is difficult to rectify. Some small projects and places are not carefully designed and selected. It is very dangerous to choose and lay lines at will. The bearing capacity of the original circuit shall be fully considered for new electrical appliances and electric equipment. If the original line does not meet the requirements, it shall be redesigned and reconstructed.<了解详情>

1. The products of wires and cables used in power system of power system mainly include overhead bare wires, bus bars (buses), power cables (plastic cables, oil paper power cables (basically replaced by plastic power cables), rubber sheathed cables, overhead insulated cables), branch cables (replacing part of bus wires), electromagnetic wires and electrical equipment wires and cables for power equipment. 2. The wires and cables used for information transmission system mainly include local telephone cables, TV cables, electronic cables, radio frequency cables, optical fiber cables, data cables, electromagnetic cables, power communication cables or other composite cables. 3. This part of instrument system is applied to almost all products except overhead bare wires, but mainly power cables, electromagnetic cables, data cables, instrument cables, etc.<了解详情>